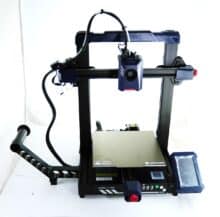

After there were already several variants of Anycubic’s 3D printer “Kobra”, the new Kobra 2 will also come onto the market in different variations. One of the latest additions is the Kobra 2 Pro. It uses the same basic design, but is supposed to support a much higher speed. While the Kobra 2 is specified up to a maximum of 300 mm/s and designed for operation at 200 mm/s, the Kobra 2 Pro is said to even allow up to 500 mm/s – and 300 mm/s is recommended.

Away from the higher speed, many elements are identical, such as the print chamber and base frame. Once again, features such as automatic leveling, a touchscreen and a removable printing plate made of spring steel are also included. Changes are therefore more to be found in the details, such as the connections: Here, the Kobra 2 Pro relies on three USB-A ports, whereas the predecessor is equipped with a USB-C port and a microSD slot. The Pro model also features Wi-Fi.

Anycubic is asking a price of 280 euros for the Kobra 2 Pro at launch [Current: $ 259.00 *]. How the 3D printer does for this price, and whether the print quality does not suffer at the high speed, we clarify in the following test.

Technical data of the Anycubic Kobra 2 Pro

| Printer Technology: | FDM |

| Dimensions (W x H x D): | 435 x 486 x 463 mm |

| Printing space (W x H x D): | 220 x 250 x 220 mm |

| Layer thickness: | 0.05 – 0.3 mm |

| Nozzle: | 4 mm |

| Maximum temperature: | 260 °C (extruder) / 110 °C (heating plate) |

| Printing speed: | 500 mm/s maximum, 300 mm/s recommended |

| Leveling: | 25-point, Inductive / Automatic |

| Material | PLA, TPU, PETG, ABS |

| Slicing Software: | GCode / Anycubic Slicer, Prusa Slicer, Cura |

| Connectors / Connectivity: | 3x USB + 1x USB (camera), WLAN |

| Control: | Touch screen |

| Weight: | 8.4 kg |

| Price (Current): | $ 259.00 * [Test time: 280 euros] |

Scope of delivery

- Delivery in finished segments

- Everything necessary is included

Anycubic delivers the Kobra 2 Pro in a plain cardboard box. Inside, encased in matching foam parts, are the individual parts of the 3D printer. The base and the frame are delivered separately, and additional elements such as the display or the extruder are also not pre-assembled.

In addition to the components of the printer itself, the manufacturer also includes numerous accessories. These include wrenches and Allen keys for assembly, a bit of green filament and a replacement nozzle in case the one installed at the factory is worn out. With that, you have everything right at hand to get started with the assembly.

Assembly & startup

- Good instructions

- Easy setup

- Simple setup

The included instructions take you step by step through the setup process. First, the frame with the Z-axis is bolted to the base and then the pressure plate is placed on top. Next, the extruder, display and filament sensor are screwed into place. Finally, only the coil holder then has to be inserted at the side and all components, for example the stepper motors, have to be connected. Anycubic has provided the cables with matching markers, so there is hardly anything that can go wrong here.

After setup, you can still tighten or loosen the toothed belts for the X- and Y-axes using the knobs provided, but in our case this wasn’t necessary at all. All that remains for setup is the software, which guides you through the process step by step. Meanwhile, the printer is automatically leveled, the filament is inserted and a resonance test is performed. During this process, the printer drives all motors with various extreme commands to detect vibrations and compensate for them in the future. According to Anycubic, this should improve quality when printing at high speeds.

If you have enough room to unpack and set up, you can get through it in a good hour – if you take your time. The entire setup process is well documented and is easy to do. Even 3D printing beginners should have no problem here.

Design & Workmanship

- Stable design

- Good build quality

The Kobra 2 Pro relies on a typical Prusa design. The control electronics are housed in the base, above which the heating plate is moved by toothed belts along a guide rail consisting of two linear shafts. The Z-movement is performed by two threaded rods, which are used to lift the entire X-axis. There, as usual, toothed belts are used again. These move the print head along another guide rail.

Interestingly, although Anycubic uses a PTFE tube for the filament, the extruder still sits directly behind the print head. Despite the high speeds targeted, this makes the print unit quite heavy. However, the axles all make a very stable impression, so this should hardly be critical.

The choice of materials and build quality is also generally praiseworthy. The Cobra 2 Pro relies on metal in many places, and all metal and plastic parts are cleanly manufactured and stable. Especially considering the price, there is nothing to criticize here. In addition, Anycubic has also struck a good note visually in our eyes, as far as that is possible with this basic design.

Connection, operation & software

- Simple menu navigation

- Print files in internal memory

- App support planned

The operation of the Kobra 2 Pro is very simple: for operation, the 3D printer must be connected to power, then you can get started directly. Various options are available via the provided menu, for example, for the WLAN connection, and a renewed auto-leveling or resonance detection. In addition, past print files are available in case you want to print something again.

If you want to start a new print, you can use a USB stick. You can simply insert it and then navigate to the desired file via the menu. Anycubic obviously relies on a resistive touch display, so you have to use a bit of force. However, you get used to this quite quickly.

As soon as the desired file is selected, the 3D printer copies it to the internal memory – 6.5 GB are provided for this. The printing process then begins, and the USB stick can be removed again directly and the next model added. Further options are also available via the menu: For example, you can subsequently adjust the hotend and hotbed temperature or pause the print.

An app will also be available by the end of the year as an alternative to the menu control. With this, users will be able to view their printer’s data live, and start and slice prints. Those who buy a camera and mount it on the printer – two threaded inserts are provided on the top – will also be able to monitor prints and create time lapses. The corresponding connection points have already been created in the printer’s menu, but the corresponding app is not yet available in the Play Store, at least not yet. So for the time being, you are limited to the menu on the device for operation, but it also offers the necessary settings and is easy to use.

Practical & printing results

- Supplied profiles only up to 300 mm/s

- Good quality at high speed

- Impeccable traction with PLA, ABS needs a lot of ground contact

In terms of build quality and operation, Anycubic’s newcomer was able to convince us, but as an important point, of course, the practice still remains. In addition to its own slicer Anycubic offers for this, on the supplied USB stick, a profile for the well-known PrusaSlicer. If you load this, you get pre-configured profiles for ABS, TPU, PETG and PLA.

Unfortunately, the promised speed of 500 mm/s for the Kobra 2 Pro is not included in any of the profiles. Instead, PLA prints at the recommended 300 mm/s, PETG at 160 mm/s, ABS at 150 mm/s and TPU at 120 mm/s. It is incomprehensible that Anycubic specifies a maximum value of 500 mm/s, for which you have to create your own profile. After all, even the mentioned values are quite impressive for the targeted price range – and the difference between 300 mm/s and 500 mm/s would probably only be noticeable in large models with many straight lines anyway.

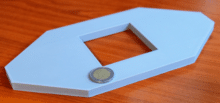

In practical use, the Kobra 2 Pro with PLA was able to fully convince us at 300 mm/s: The print head literally races across the printing plate and jumps back and forth at a tremendous speed. The printer’s construction is stable enough for the accelerations – nothing wobbles or vibrates. However, the high accelerations naturally affect the printer as a whole. Therefore, you should place it on a very stable base.

In testing, we didn’t have a single misprint with PLA, and despite the high speed, most of the structures created look excellent. Minor imperfections do occasionally occur, with some models showing a small “seam”, for example. In view of the high printing speed and the equally imperfect competition, this can be ignored without any problems.

The Kobra 2 Pro also mastered our tests with ABS at least satisfactorily. Once again, there is nothing to complain about in terms of the basic print quality. In contrast to PLA, however, the grip can become a problem with ABS. If the lower parts of the model cool down, it can sometimes flake off. Those who want to use the Kobra 2 Pro for ABS should therefore ideally provide a warmer environment – for example, with an enclosure. However, those who do not only have filigree base structures as a connection will not have a problem without it – and can achieve good results.

Lastly, we also liked the maintenance, because it is virtually not necessary. The only work step between two prints is removing the 3D models, which is very easy thanks to the included printing plate: When the plate is bent, the prints on it simply fall off. The impeccably working auto-leveling and filament sensor also worked well. As soon as the filament was empty, printing was automatically paused. After replacing it, it could be restarted without any problems.

Conclusion

For a starting price of 280 euros, Anycubic has launched the Kobra 2 Pro, a 3D printer that is supposed to stand out for its particularly high printing speed. And even though no profile for the 500 mm/s mentioned as the maximum is included ex-works, the 300 mm/s offered are also impressive. The Cobra 2 Pro prints at a very high speed and still achieves a good quality. Only those who print a lot with ABS have to pay attention to enough traction. With PLA, on the other hand, the Cobra 2 Pro is absolutely uncritical and also very low-maintenance.

At the same time, other points are also right, such as the build quality or the simple setup. The operation via the touch menu is just as successful in our eyes. It remains to be seen how the upcoming smartphone control via app will turn out.

Even without this addition, the Kobra 2 Pro is a successful product in our eyes: Anycubic has gotten a lot out of the basic Prusa design. At the called price of currently $ 259.00 * [test time: 280 euros], the 3D printer is thus worth a recommendation.

Anycubic Kobra 2 Pro

Usability

Assembly

Noise level

Print quality

Value for money

90/100

A good, low-maintenance 3D printer that delivers good results even at high printing speeds.

No replies yet

Neue Antworten laden...

Gehört zum Inventar

Beteilige dich an der Diskussion in der Basic Tutorials Community →