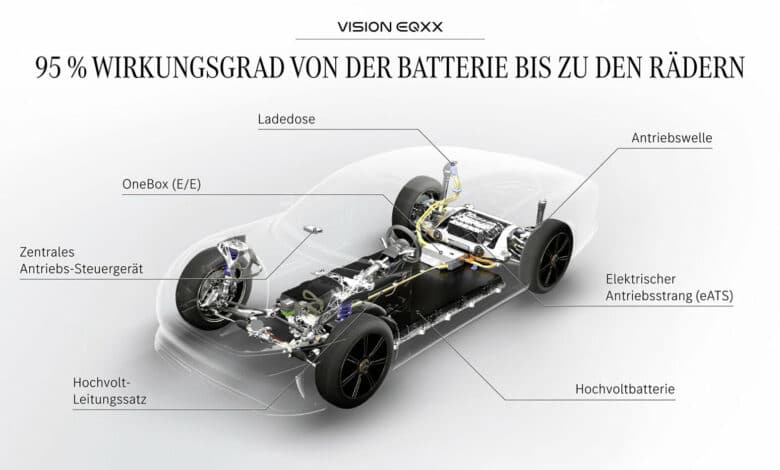

In recent weeks and months, we have seen a lot of exciting news on the subject of electromobility. These include not only groundbreaking design studies, but also technical innovations, some of which are revolutionary. For example, there is the Vision EQXX from Mercedes, which is supposed to enable a range of just over 1,000 km with only one battery charge. In the field of e-cars, that’s a real bang for the buck. But if parent company Daimler has its way, this should not be an exception, but just a first taste of the future. That’s because the automotive group plans to manufacture intelligent drives that set new standards in energy efficiency.

Development with its own signature

The boom in electric cars has ensured that many automakers have not even had the time to conduct research around the topic of electromobility. Opel, Mercedes and VW, for example, simply used the motors and drives already available on the market. VW was the first to make itself independent of this by developing its own platform, which we can now admire more and more frequently on German roads with the ID.3 and ID.4. Now the well-known carmaker Daimler also wants to set itself apart from the masses and develop its own batteries and the corresponding drive systems in the future. In doing so, the company is apparently planning something big.

In 2024 it should start

It should not be long before Daimler develops its own drives. For example, the models in the EQ series from 2024 are already to be equipped with the company’s own technology. The reason for the switch to in-house technology is apparently the pursuit of greater energy efficiency. This clearly shows that Daimler is also changing its strategy with the arrival of electromobility in the broad mass of society. Whereas Mercedes & Co. used to focus primarily on comfortable handling and performance, the staying power of the installed battery now plays a major role.

This can be seen not least in the fact that Mercedes has emphasized the potential range of over 1,000 km for its “Vision EQXX” prototype above all else (we reported). At the same time, Daimler wants to put a “made in Germany” label on the whole thing. After all, the traditional company relies on manufacturing in Stuttgart – the headquarters of Mercedes-Benz.

Refusing third-party components

However, the company’s own drive system seems to be just the beginning. In perspective, Mercedes would like to do away with using components from other manufacturers as far as possible when building its own vehicles. Ultimately, the company wants to achieve maximum performance and efficiency by making every single component work perfectly together. What Daimler has already achieved in its internal combustion engines leaves much to be desired in the area of electromobility.

With the exception of the currently available top-of-the-range EQS model, these are almost exclusively combustion engine vehicles whose classic engine has been unceremoniously replaced by an electric motor and drive. What is possible when everything comes from a single source is demonstrated by the competition in the form of young, lively car manufacturers. After all, if you focus only on building e-cars from the outset, you can achieve perfect interaction between all the components. Tesla sends its regards.

Another battery production in Germany

So slowly, Germany seems to be emerging as a real El Dorado for manufacturers of battery systems for electric cars. Given its storied past as the birthplace of the car, however, this is hardly surprising. Daimler, for example, would also like to develop and produce its own batteries in Germany in the future. However, there is another reason why there will be no outsourcing abroad. Daimler’s works council has insisted that production should continue to take place in Germany.

If you compare the construction of a combustion engine car with that of an electric car, it quickly becomes clear that far fewer people are needed to produce a vehicle. After all, it is primarily the drive and engine that are manufactured at great expense. So to prevent thousands of jobs being cut, the Stuttgart plant is to produce not only the electric drive but also the battery technology in the future. The plant in Berlin is also to be integrated as demand grows.

No replies yet

Neue Antworten laden...

Neues Mitglied

Beteilige dich an der Diskussion in der Basic Tutorials Community →